|

|

||

|

|

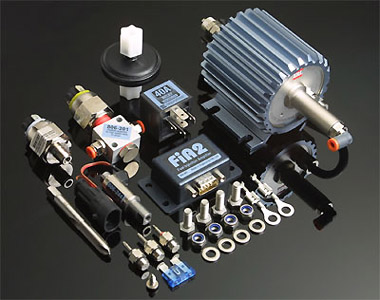

Is water injection new?: No. Water injection was used during WWII to surpress detonation in fighter aircraft and increase their service ceiling. WATER? Water exists mainly in a liquid state because that is its most stable inter-molecular structure. When we apply heat energy to it, its molecules begin to expand: a great deal of heat is absorbed during this process owing to water's specific heat capacity - approximately 4.2kJ/(kg.K). When the water changes from the liquid to gas state, large amount of heat energy is consumed in sustaining the process. The latent heat of evaporation is 2256kJ/kg, approximately six times more than gasoline! Does the water "burn" in the engine?: No. The water simply converts from a vapor to a gaseous state which absorbs huge amounts of heat, due to the energy required to transform it. SO WHAT? Because of its huge specific- and latent- heat capacity, water is the perfect liquid for regulating excess heat under certain engine-operating conditions, for example induction charge air cooling; but its biggest contribution is inside the combustion chamber where, under excessive loading, pre-ignition and detonation can otherwise occur. Such abnormal combustion is particularly common in force induction engines, where exhaust temperature can exceed 1600°C in a rotary engine! Will water injection increase my horsepower?: Yes, but not directly. Water injection works to eliminate detonation, also known as knock. The big gains come from the ability to increase boost as well as the full ignition advance allowed by the ECU when it does not detect knock. While the cooling of the intake charge will produce some power increases, those increases are cancelled by the charge space occupied by the water vapor. In other words, there is slightly less room for air and fuel. However, by using up to 40 percent alcohol with the water, additional cooling takes place before the turbo, and the alcohol works as a fuel in the charge. This results in an increase in power. TURBO-CARS are easily upgraded in performance just by adjusting the boost pressure and upgrading the engine management system; but the hidden drawback of this solution is that even more fuel is being dumped -- as a coolant! -- to compensate for standard engine-cooling arrangements (inside the engine bay your fast-road car has more-or-less the same radiators and cooling fans as the family car next door). But as you upgrade your power-upgrade, you will get to the point where the fuel becomes so rich, and the flame is burning so slowly, that power is being lost rather than gained. HELP! Help is indeed at hand! The ERL Aquamist system, using sophisticated electronics to process engine-data, injects a precisely-metered quantity of coolant: not gasoline, but water, six times more effective, and freely available! (sometimes cut with alcohol) We eliminate fuel-dumping, leaving your air/fuel ratio unaffected, enabling maximum power to be extracted from the engine. To ensure that each rotor receives exactly the same dosage, we deliver the coolant in a fine mist: not only does Aquamist reduce the risk of damage ... it steam-cleans your engine with every rotation. THERE'S MORE ... The Aquamist system offers a full range of diagnostic features, enabling you to detect blocked nozzles, cut water-pipes, and all sorts of other smashing things. If track record and expertise is what you want, don't wait for your favorite racing driver to tell you about Aquamist on TV: it might be too late ... FOR THE MONTH OF DECEMBER ONLY!! TAKE AN ADDITIONAL 10% OFF LISTED PRICE

|

|

Lobby | Drivers Lounge | Tech Shop | Race Shop | Showroom | Contact Us |

|||

| Copyright © 2003 rotorsportsracing.com - All Rights Reserved. 704-933-6222 |